How strong wind resistance can wind power photovoltaic tooling tools withstand? Can they be used stably in windy weather?

Release Time : 2025-09-01

The high-wind resistance of wind power photovoltaic tooling tools is closely related to the physical strength of their all-iron plate material, the rationality of their overall structural design, and their suitability for wind power and photovoltaic (PV) operation scenarios. Their stability in high winds directly impacts the safety and efficiency of outdoor installation, operation, and maintenance. In wind power and PV projects, operations often take place in open, outdoor locations (such as mountaintops, suburban areas, and offshore platforms). These areas experience strong winds year-round, especially during strong spring and winter winds. These forces not only exert horizontal thrust on the tooling but can also cause tool shaking and displacement. Inadequate wind resistance can compromise accuracy at best, and even lead to tool drop, component damage, and even operator safety threats. Therefore, the high-wind resistance of wind power photovoltaic tooling tools is a key factor in ensuring outdoor operation safety.

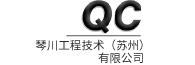

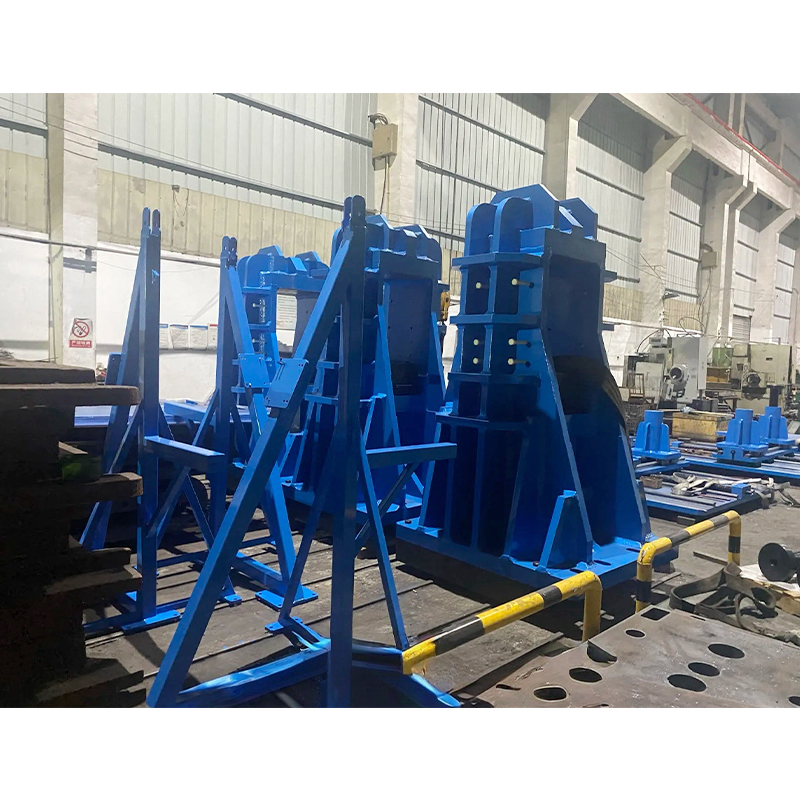

From a material perspective, the all-iron plate material provides excellent wind resistance for tooling tools—the plate's inherent strength and rigidity make it less susceptible to bending or deformation in strong winds. Compared to materials like plastic and aluminum alloy, sheet metal boasts a higher density and a more stable structure, allowing it to withstand stronger wind impacts while maintaining its shape. In particular, sheet metal components processed through processes like cold rolling and welding further enhance their overall mechanical properties, effectively resisting the tensile and impact forces exerted on tools by strong winds. For example, core components like the tool's support frame and mounting brackets are constructed entirely of sheet metal, creating a solid "load-bearing skeleton" that minimizes frame sway even in sudden strong winds, laying the foundation for the tool's overall stability.

The structural design of wind power photovoltaic tooling tools is a key factor in determining their ability to withstand strong winds and maintain their stability in windy conditions. High-quality tooling utilizes a dual design principle of "low wind resistance + strong fixation": To optimize wind resistance, the tool's appearance is minimized, with fewer protruding corners and hollow structures to prevent strong winds from forming vortices on the tool surface, thereby reducing the drag coefficient. Some tools also feature hollowing in non-load-bearing areas to reduce weight while allowing for smooth airflow, further reducing wind thrust on the tool. In terms of structural design, the tools are equipped with multiple high-strength fixing devices, such as adjustable ground anchors, snap-on connectors, and weighted bases. Ground anchors can be driven deep into the ground or fixed to photovoltaic mounts or wind turbine towers, creating multiple points of fixation. Weighted bases increase the weight of the tool, enhancing wind resistance and stability. Snap-on connectors ensure a tight connection between components, preventing strong winds from loosening or separating them. Together, these features prevent the tool from shifting or shaking in windy conditions.

The tool's compatibility with the work surface also affects its stability in high winds. The design of wind power photovoltaic tooling tools fully considers the connection method to the photovoltaic panel mount and wind turbine equipment base, ensuring an integrated fixation between the tool and the surface. For example, tooling tools used for photovoltaic module installation are designed with slots that match the PV mount rails. During installation, they snap directly into the rails and lock with bolts, preventing the tool from sliding along the rails due to strong winds. Tooling tools used for wind turbine tower maintenance are equipped with curved clamps that fit snugly against the tower's exterior. Anti-slip pads increase friction, ensuring a secure hold on the tower even in high-altitude, strong winds, preventing rotation or slipping. This precise adaptation to the carrier further enhances the tool's resistance to strong winds.

In actual outdoor work scenarios, standard wind power photovoltaic tooling tools maintain excellent stability in windy conditions, meeting operational requirements. For example, in outdoor environments with wind speeds of force 6-7 (approximately 10-17 m/s), a photovoltaic panel mounting platform constructed entirely of iron plates will not experience noticeable sway in its support frame, and the non-slip steps on the platform's surface can stably support the weight of operators and panels. Even in sudden, high winds exceeding force 8 (speeds exceeding 17 m/s), as long as the tools are secured according to specifications (e.g., anchors are properly installed and connectors are tightened), the structure remains stable and will not shift or tip over. Some high-specification tooling undergoes wind tunnel testing to simulate the forces under various wind conditions, further optimizing its structural design to ensure safe use even in extreme winds.

It is important to note that the wind resistance and stability of wind power photovoltaic tooling tools also depend on proper installation and operation. Even if the tool itself has excellent wind resistance, it may experience a loss of stability in high winds if the fixing device is not fully tightened during installation, the anchor depth is insufficient, or the tool is used beyond its rated load capacity. Furthermore, after prolonged outdoor use, rust and wear on the tool's connectors can affect the tool's securement and weaken its ability to withstand strong winds. Therefore, strict installation and commissioning according to the manual are essential before use. Tool components must be regularly inspected and any aging or damaged parts promptly replaced to maximize the tool's high wind resistance.

Wind power photovoltaic tooling tools, thanks to their high strength from all-iron plate, low wind resistance, strong fixing design, and precise fit with the work surface, offer excellent wind resistance and stability in windy conditions, fully meeting the environmental requirements of outdoor wind power and photovoltaic operations. Their strong wind resistance not only ensures safe and efficient operation but also adapts to diverse climate conditions, providing reliable tool support for the long-term advancement of wind power and photovoltaic projects, making them indispensable equipment for outdoor renewable energy operations.