How does the crusher improve crushing efficiency in the metallurgical and mining equipment department suite?

Release Time : 2025-09-25

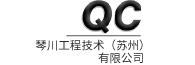

Crusher, as a core piece of equipment within the metallurgical and mining equipment suite, requires coordinated efforts across multiple dimensions, including equipment selection, process optimization, parameter control, and maintenance management. Equipment selection must be closely aligned with ore characteristics, requiring specific crusher types for ores of varying hardness and particle size. For example, jaw crushers are suitable for coarse crushing of high-hardness ores, their powerful extrusion crushing method efficiently handling bulky material. Cone crushers excel in secondary and fine crushing, employing a laminated crushing principle that achieves uniform particle size and minimizes wear on wear parts. Impact crushers use impact energy to crush medium-hardness ores, resulting in fine-grained output and low energy consumption. For ore with high moisture content or high viscosity, equipment with overload protection is preferred to avoid efficiency losses caused by material blockage.

Process optimization is key to improving efficiency. Closed-circuit crushing processes, which recycle screening equipment and crushers, return material that does not meet particle size requirements for re-crushing, significantly improving yield. For example, in iron ore concentrators, a three-stage closed-circuit crushing process can keep the final product particle size within a reasonable range, reducing the load on the grinding stage. Furthermore, pre-screening can remove fine particles, avoid repeated crushing, and reduce energy consumption. For multi-stage crushing systems, the crushing ratios of each stage must be properly distributed to avoid efficiency bottlenecks caused by excessive load on any one stage.

Precise control of process parameters directly impacts crushing results. Speed adjustment must balance efficiency and wear. A high swing frequency of the jaw crusher's movable jaw accelerates liner wear, while a low frequency results in insufficient throughput. The cone crusher's movable cone speed must be optimized based on ore hardness, with higher speeds required to provide sufficient crushing force for hard ores. The discharge port size must be adjusted dynamically. A small size can cause frequent blockages, while a large size can result in excessive finished product particle size. Feedback adjustments must be made through real-time monitoring of the discharge particle size distribution. Feed control is equally important. Uniform feeding prevents equipment overload or idling. Linked adjustment of the vibrating feeder and belt conveyor ensures stable feed.

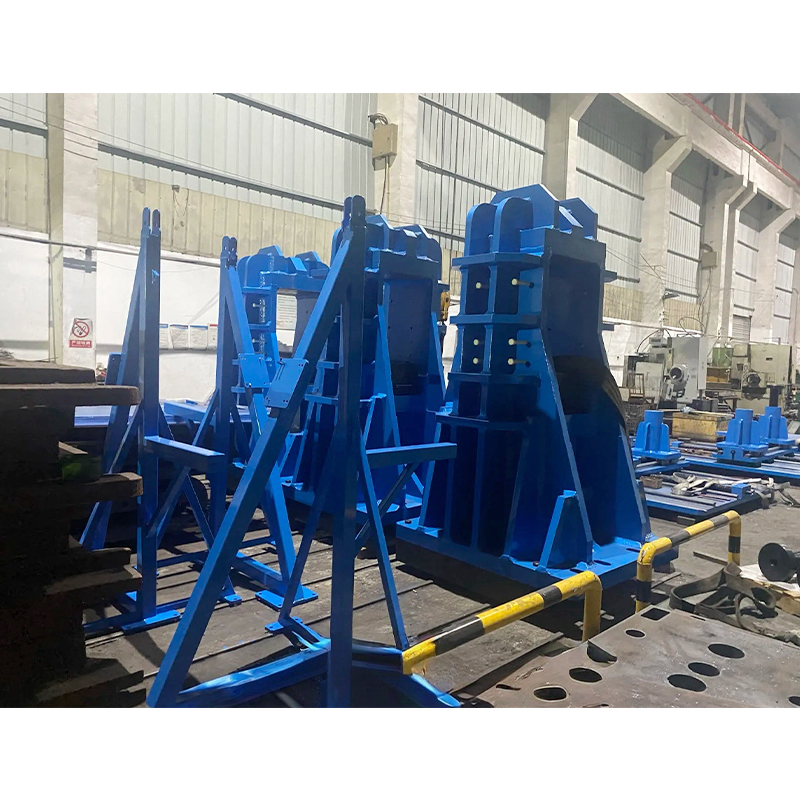

Equipment maintenance and overhaul are fundamental to ensuring efficiency. Regularly inspect the wear of vulnerable parts such as the crushing chamber liner and tooth plates, and replace them promptly to prevent efficiency losses caused by component failure. For example, worn conical crusher liners alter the crushing chamber shape, leading to uneven particle size. These components require periodic replacement or welding repairs. Lubrication system maintenance is crucial. Insufficient lubrication of transmission components such as gears and bearings can cause overheating or even seizure. Select the appropriate grease based on operating conditions and replenish it regularly. Furthermore, cleaning residual material inside the crusher can prevent increased startup resistance and shorten standby time.

The application of intelligent control technology offers a new path to improving efficiency. Sensors installed in key crusher locations monitor parameters such as vibration, temperature, and current in real time. Data analysis can predict equipment failures and preemptively schedule maintenance. For example, abnormal fluctuations in motor current may indicate a feed blockage or transmission system failure. Prompt action can avoid unplanned downtime. Some advanced equipment is equipped with automatic adjustment systems that dynamically adjust the discharge opening size or speed based on changes in ore hardness and particle size, achieving adaptive crushing.

Operator skill significantly impacts efficiency. Professional training can help operators become familiar with equipment performance and process requirements, preventing efficiency losses caused by misoperation. For example, correctly understanding the relationship between feed rate and crusher load can reduce the frequency of material blockages. Familiarity with the crushing characteristics of different ores allows for targeted parameter adjustments to optimize results. Furthermore, establishing standardized operating procedures and maintenance systems ensures long-term, stable operation of the equipment.

Improving crusher efficiency requires comprehensive management throughout the equipment lifecycle. From precise matching during the selection phase, to continuous process optimization, to dynamic balancing of parameter control, supplemented by intelligent maintenance and personnel skills development, comprehensive improvements in crushing efficiency can be achieved, providing solid support for cost reduction and efficiency improvement in metallurgical mining operations.