How to achieve dynamic balance control when wind power photovoltaic tooling tools are hoisting blades?

Release Time : 2025-10-20

During blade installation with wind power photovoltaic tooling tools, dynamic balance control is a key component for ensuring safety and improving efficiency. Blades, as key components of wind turbines, must be installed under complex environmental conditions. Dynamic balance control is directly related to installation accuracy, equipment safety, and subsequent operational stability. Through the synergy of multiple technologies, wind power photovoltaic tooling tools achieve comprehensive dynamic balance optimization, from mechanical structure to intelligent algorithms.

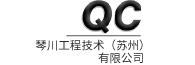

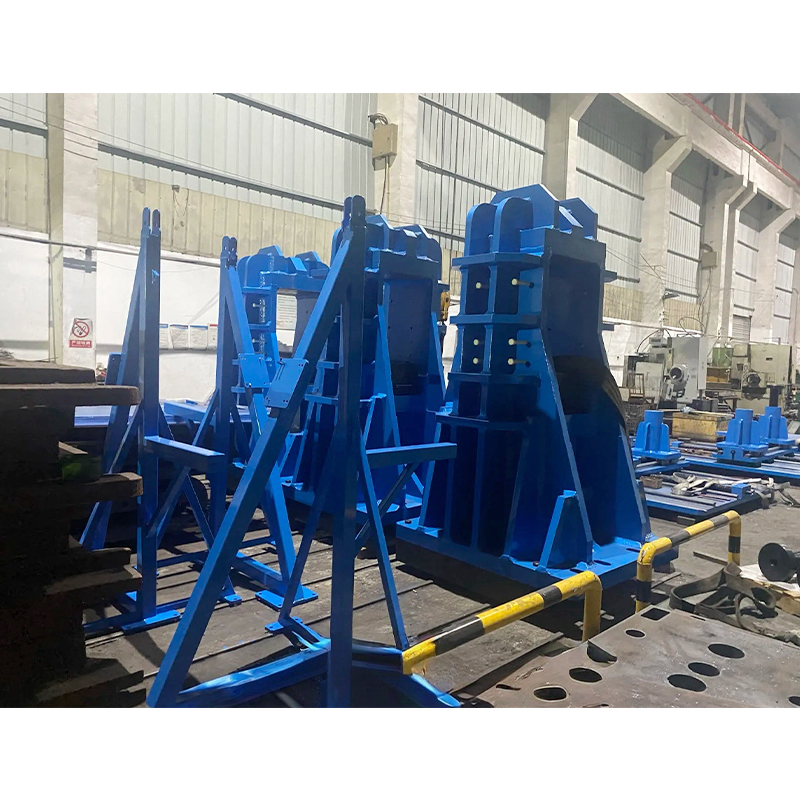

Mechanically, the wind power photovoltaic tooling tools utilize a symmetrical lifting fixture design to evenly distribute loads and reduce eccentric torque. For example, when lifting a single blade, the main fixture body secures the blade using a C- or SC-type structure, with dual-point clamping mechanisms at the root and tip. This design evenly transfers the blade's weight to the lifting fixture, preventing wobbling caused by unilateral forces. Furthermore, the lifting fixture features a built-in counterweight adjustment module that adjusts the overall center of gravity based on blade model or clamping location, ensuring that the combined center of gravity of the tool and blade remains aligned on the vertical axis during installation, mitigating the risk of dynamic imbalance.

The introduction of a hydraulic system further improves the response speed of dynamic balancing. The multi-point automatic balancing and positioning hydraulic system independently controls the oil pressure at each support point, adjusting the spreader's posture in real time. When blades deflect due to wind or wave loads, the system rapidly adjusts the extension and retraction of the corresponding hydraulic cylinder to compensate for the displacement. For example, during offshore installation, the hydraulic system can respond to wind speed changes within milliseconds, adjusting the spreader's tilt angle to offset blade motion, achieving millimeter-level docking accuracy. This active control approach significantly outperforms traditional passive balancing and significantly reduces the need for manual intervention.

Sensor networks and data fusion technologies provide real-time decision-making for dynamic balancing. Wind power photovoltaic tooling tools integrate high-precision vibration sensors, inclinometers, and laser rangefinders to continuously collect data on blade posture, spreader stress, and ambient wind conditions. Using a multi-source data fusion algorithm, the system accurately identifies the blade's six degrees of freedom (6DOF) motion, including lateral swing, longitudinal pitch, and axial torsion. For example, if sensors detect abnormal vibration at the blade tip, the algorithm, combined with current wind speed, spreader load, and other parameters, quickly locates the cause of the imbalance and generates adjustment instructions, ensuring precise dynamic balancing control.

Intelligent control algorithms are the core driving force behind dynamic balancing. Model Predictive Control (MPC)-based algorithms build a dynamic model of the lifting system to predict the blade's trajectory in the future and optimize control inputs. For example, during blade-hub docking, the algorithm calculates the optimal lift adjustment sequence based on current position errors, wind speed forecasts, and hydraulic system response characteristics, ensuring blade docking with minimal vibration. Furthermore, adaptive control technology automatically adjusts model parameters to adapt to varying blade models, lifting environments, and operating conditions, ensuring the robustness of the control strategy.

Human-machine collaboration enhances the operability of dynamic balancing. Wind power photovoltaic tooling tools feature a visual monitoring interface that displays blade position, stress distribution, and balance status in real time, alerting operators to risks through color coding or warning signals. For example, if the system detects that the relative position of the blade and hub exceeds a safe threshold, it immediately triggers an audible and visual alarm and locks the lift movement until the problem is resolved. Furthermore, remote control functionality allows technicians to adjust parameters from the control room, reducing on-site operational risks and improving lifting efficiency.

From an overall perspective, the dynamic balancing control of wind power photovoltaic tooling tools significantly improves the safety and economic efficiency of lifting. By reducing blade sway, it reduces the failure rate of docking and the risk of bolt damage, avoiding the increased costs associated with repeated lifting. Furthermore, dynamic balancing technology extends the operability window, enabling lifting operations at higher wind speeds and improving the controllability of project schedules. Furthermore, the modular design enables tooling to be quickly adapted to different machine models, reducing equipment idleness and providing strong support for the efficient development of the wind power and photovoltaic industries.