Can a crusher maintain long-term operational stability under high-intensity impact loads?

Release Time : 2025-12-15

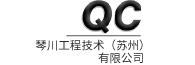

In the harsh environments of metallurgical and mining operations, the crusher, like the "teeth" of an industrial behemoth, gnaws at hard ores, metallurgical waste, or high-silica rocks day after day. Each engagement is accompanied by intense impact, vibration, and alternating stress, posing a severe test to the structural strength and dynamic stability of the equipment. Therefore, whether a crusher can maintain long-term operational stability under high-intensity impact loads is not only related to production continuity but also directly affects operational safety and operating costs.

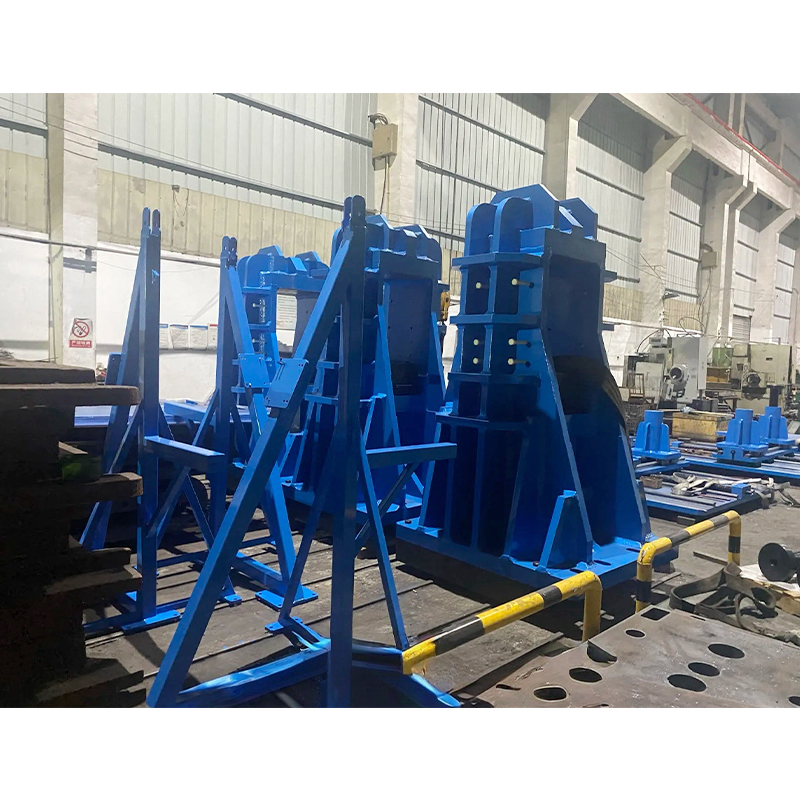

This stability does not stem from simple "heavyweight" or "robust" construction, but rather from the deep synergy of materials science, structural mechanics, and system integration. First, core load-bearing components—such as the frame, spindle, moving jaw, or grinding bowl—are typically made of high-strength alloy cast steel or forgings that have undergone special heat treatment. Their internal structure is dense, with refined grains, possessing sufficient rigidity to resist deformation while retaining appropriate toughness to absorb impact energy and avoid brittle fracture. Even under continuous high-frequency impacts, the material can maintain its mechanical properties without significant degradation.

Secondly, the overall structural design fully considers the transmission path of dynamic loads. Engineers optimize stress distribution through finite element analysis to avoid localized stress concentrations; key connections utilize high-strength pre-tightened bolts or integral casting processes to eliminate weak points; the frame is often designed as a closed box-type structure, forming a stable mechanical framework that effectively suppresses vibration propagation. This "rigid-flexible" architecture allows the equipment to rapidly disperse energy across the entire structure when subjected to instantaneous peak loads, rather than concentrating it at a single point, thus preventing the initiation and propagation of fatigue cracks.

Furthermore, the reliability of auxiliary systems is equally crucial. An efficient lubrication system ensures that bearings and gears receive continuous clean oil film protection in high-temperature, dusty environments, preventing overheating and seizure due to dry friction; hydraulic overload protection devices automatically release pressure when foreign objects enter or overload occurs, preventing damage to the main drive system; and advanced vibration-damping mounts or foundation isolation designs further isolate vibration transmission to the plant or foundation, protecting surrounding equipment and building structures.

From an operational perspective, long-term stability means less unplanned downtime, lower maintenance frequency, and more predictable maintenance cycles. For a large mine, any interruption in the crushing process will bring both upstream mining and downstream conveying systems to a standstill, resulting in enormous losses. A crusher that remains rock-solid under harsh conditions is the cornerstone ensuring the efficient operation of the entire production line.

At a deeper level, this stability reflects the manufacturer's understanding and respect for real-world working conditions. It's not an ideal model from a laboratory, but the culmination of countless field trials and continuous optimizations in mining. Whether it's the challenge of heat dissipation in the oxygen-deficient environment of high altitudes or the additional load from mud adhesion during the rainy season, the equipment must handle it all with ease.

Ultimately, the crusher's long-term operational stability under high-intensity impact loads is not accidental, but the most robust interpretation of "reliability." It silently perseveres amidst roar and vibration, demonstrating the composure and durability expected of industrial equipment in the violent process of crushing stone into sand—with a steel body, it bears immense force, safeguarding the efficient conversion of every ton of ore.

This stability does not stem from simple "heavyweight" or "robust" construction, but rather from the deep synergy of materials science, structural mechanics, and system integration. First, core load-bearing components—such as the frame, spindle, moving jaw, or grinding bowl—are typically made of high-strength alloy cast steel or forgings that have undergone special heat treatment. Their internal structure is dense, with refined grains, possessing sufficient rigidity to resist deformation while retaining appropriate toughness to absorb impact energy and avoid brittle fracture. Even under continuous high-frequency impacts, the material can maintain its mechanical properties without significant degradation.

Secondly, the overall structural design fully considers the transmission path of dynamic loads. Engineers optimize stress distribution through finite element analysis to avoid localized stress concentrations; key connections utilize high-strength pre-tightened bolts or integral casting processes to eliminate weak points; the frame is often designed as a closed box-type structure, forming a stable mechanical framework that effectively suppresses vibration propagation. This "rigid-flexible" architecture allows the equipment to rapidly disperse energy across the entire structure when subjected to instantaneous peak loads, rather than concentrating it at a single point, thus preventing the initiation and propagation of fatigue cracks.

Furthermore, the reliability of auxiliary systems is equally crucial. An efficient lubrication system ensures that bearings and gears receive continuous clean oil film protection in high-temperature, dusty environments, preventing overheating and seizure due to dry friction; hydraulic overload protection devices automatically release pressure when foreign objects enter or overload occurs, preventing damage to the main drive system; and advanced vibration-damping mounts or foundation isolation designs further isolate vibration transmission to the plant or foundation, protecting surrounding equipment and building structures.

From an operational perspective, long-term stability means less unplanned downtime, lower maintenance frequency, and more predictable maintenance cycles. For a large mine, any interruption in the crushing process will bring both upstream mining and downstream conveying systems to a standstill, resulting in enormous losses. A crusher that remains rock-solid under harsh conditions is the cornerstone ensuring the efficient operation of the entire production line.

At a deeper level, this stability reflects the manufacturer's understanding and respect for real-world working conditions. It's not an ideal model from a laboratory, but the culmination of countless field trials and continuous optimizations in mining. Whether it's the challenge of heat dissipation in the oxygen-deficient environment of high altitudes or the additional load from mud adhesion during the rainy season, the equipment must handle it all with ease.

Ultimately, the crusher's long-term operational stability under high-intensity impact loads is not accidental, but the most robust interpretation of "reliability." It silently perseveres amidst roar and vibration, demonstrating the composure and durability expected of industrial equipment in the violent process of crushing stone into sand—with a steel body, it bears immense force, safeguarding the efficient conversion of every ton of ore.