How can blow molding machines be revitalized through core component upgrades?

Release Time : 2025-12-29

In the industrial system of large-scale plastic product manufacturing, blow molding technology has long held a significant position in packaging, daily chemicals, automotive, and medical fields due to its high efficiency, low cost, and suitability for hollow container manufacturing. While the blow molding machine, as the core equipment of this process, is categorized as "traditional industrial equipment," its structural complexity, control precision, and the performance of key components directly determine the wall thickness uniformity, dimensional stability, and production efficiency of the product. Especially driven by increasingly stringent environmental regulations and the upgrading of intelligent manufacturing, blow molding machines are achieving a leap from "usable" to "highly efficient, energy-saving, and intelligent" through continuous optimization of core components.

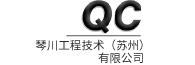

The basic working principle of a blow molding machine is to place a heated and softened plastic preform into a mold, inflate it with high-pressure gas to fit the mold cavity, and then cool it to form a hollow product. Common types include extrusion blow molding, injection blow molding, and stretch blow molding (such as equipment specifically for PET bottles). While the process may seem straightforward, achieving high-consistency mass production relies on the coordinated operation of multiple precision subsystems: from the plasticizing system, mold clamping mechanism, and blowing device to temperature control and hydraulic units, each link has a decisive impact on the final quality.

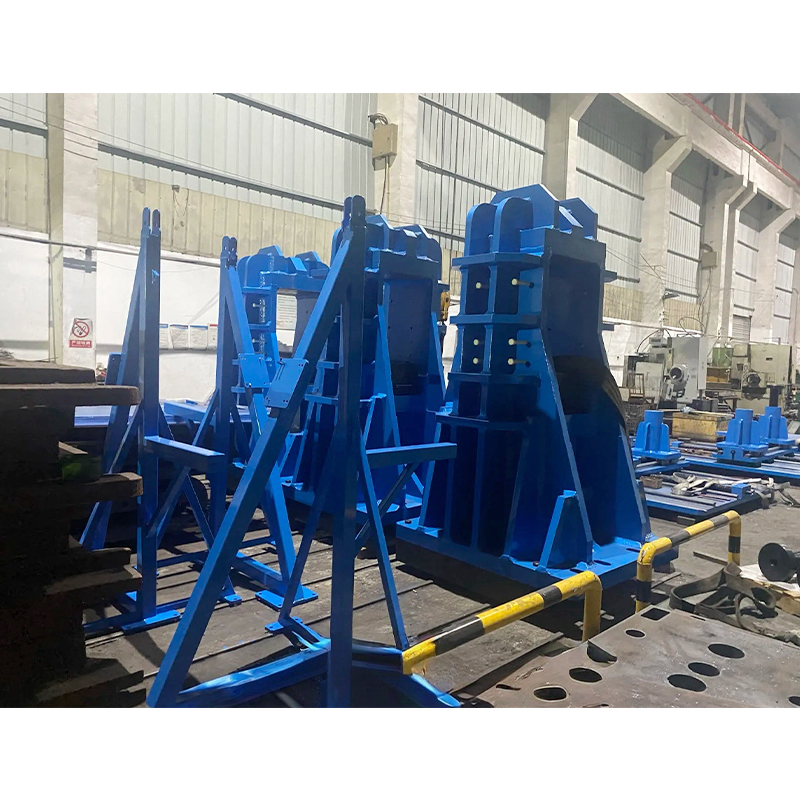

The core components of the equipment are crucial for performance assurance. The screw and barrel assembly, as the heart of the plasticizing system, must possess excellent wear resistance, thermal stability, and mixing uniformity. High-end blow molding machines generally employ bimetallic alloy screws or surface nitriding treatments to meet the processing requirements of different materials such as HDPE, PP, and PC. The mold clamping mechanism often uses hydraulic or servo-electric drives to ensure stable and reliable clamping forces of up to hundreds of tons, preventing flash caused by mold expansion during blowing. The blowing system, composed of the blow needle and air tank, must achieve millisecond-level response and precise pressure control to ensure that key indicators such as bottle bottom thickness and neck concentricity meet standards.

In recent years, the intelligent upgrades of blow molding machines have focused on control systems and energy-saving technologies. Modern blow molding machines are generally equipped with PLC or industrial PC control systems, supporting wall thickness programming (e.g., 10–32 point axial control), mold temperature zone management, and real-time production data acquisition. Operators can set process parameters via touchscreen, and the system automatically compensates for the impact of ambient temperature changes on parison sagging. Simultaneously, servo motor-driven hydraulic systems or all-electric models significantly reduce energy consumption, saving 30%–50% more energy than traditional quantitative pump systems, and reducing maintenance issues caused by oil temperature rise.

In the context of sustainable development, blow molding machines also play a crucial role in promoting a circular economy. An increasing number of machines support high-proportion recycled material (rPET, rHDPE) processing and integrate online impurity detection and rejection functions to ensure the quality of recycled products. Some models are also equipped with waste heat recovery devices, using the heat from cooling water to preheat raw materials or for workshop heating, further reducing the carbon footprint.

For equipment manufacturers, providing reliable spare parts supply and rapid technical service is equally important. Traditional blow molding machines have a service life of 10–15 years, during which time vulnerable parts such as seals, heating coils, and sensors need to be replaced regularly. Manufacturers with comprehensive spare parts inventories and localized service teams can significantly reduce customer downtime losses. Furthermore, retrofitting services for older equipment—such as adding servo systems, upgrading control interfaces, and optimizing mold interfaces—are also effective means of extending equipment lifecycles.

From a mineral water bottle to a car fuel tank, from a pharmaceutical eye drop bottle to a large chemical drum, the blow molding machine silently supports the daily operation of modern society. While lacking a dazzling appearance, it embodies the modern value of "traditional equipment" through its robust mechanical performance and continuous technological evolution. In the future, with the widespread adoption of bio-based plastics, ultra-lightweight design, and digital twin operation and maintenance, the blow molding machine will continue to find a balance between green manufacturing and efficient production, providing a solid and flexible manufacturing foundation for the global packaging industry.

The basic working principle of a blow molding machine is to place a heated and softened plastic preform into a mold, inflate it with high-pressure gas to fit the mold cavity, and then cool it to form a hollow product. Common types include extrusion blow molding, injection blow molding, and stretch blow molding (such as equipment specifically for PET bottles). While the process may seem straightforward, achieving high-consistency mass production relies on the coordinated operation of multiple precision subsystems: from the plasticizing system, mold clamping mechanism, and blowing device to temperature control and hydraulic units, each link has a decisive impact on the final quality.

The core components of the equipment are crucial for performance assurance. The screw and barrel assembly, as the heart of the plasticizing system, must possess excellent wear resistance, thermal stability, and mixing uniformity. High-end blow molding machines generally employ bimetallic alloy screws or surface nitriding treatments to meet the processing requirements of different materials such as HDPE, PP, and PC. The mold clamping mechanism often uses hydraulic or servo-electric drives to ensure stable and reliable clamping forces of up to hundreds of tons, preventing flash caused by mold expansion during blowing. The blowing system, composed of the blow needle and air tank, must achieve millisecond-level response and precise pressure control to ensure that key indicators such as bottle bottom thickness and neck concentricity meet standards.

In recent years, the intelligent upgrades of blow molding machines have focused on control systems and energy-saving technologies. Modern blow molding machines are generally equipped with PLC or industrial PC control systems, supporting wall thickness programming (e.g., 10–32 point axial control), mold temperature zone management, and real-time production data acquisition. Operators can set process parameters via touchscreen, and the system automatically compensates for the impact of ambient temperature changes on parison sagging. Simultaneously, servo motor-driven hydraulic systems or all-electric models significantly reduce energy consumption, saving 30%–50% more energy than traditional quantitative pump systems, and reducing maintenance issues caused by oil temperature rise.

In the context of sustainable development, blow molding machines also play a crucial role in promoting a circular economy. An increasing number of machines support high-proportion recycled material (rPET, rHDPE) processing and integrate online impurity detection and rejection functions to ensure the quality of recycled products. Some models are also equipped with waste heat recovery devices, using the heat from cooling water to preheat raw materials or for workshop heating, further reducing the carbon footprint.

For equipment manufacturers, providing reliable spare parts supply and rapid technical service is equally important. Traditional blow molding machines have a service life of 10–15 years, during which time vulnerable parts such as seals, heating coils, and sensors need to be replaced regularly. Manufacturers with comprehensive spare parts inventories and localized service teams can significantly reduce customer downtime losses. Furthermore, retrofitting services for older equipment—such as adding servo systems, upgrading control interfaces, and optimizing mold interfaces—are also effective means of extending equipment lifecycles.

From a mineral water bottle to a car fuel tank, from a pharmaceutical eye drop bottle to a large chemical drum, the blow molding machine silently supports the daily operation of modern society. While lacking a dazzling appearance, it embodies the modern value of "traditional equipment" through its robust mechanical performance and continuous technological evolution. In the future, with the widespread adoption of bio-based plastics, ultra-lightweight design, and digital twin operation and maintenance, the blow molding machine will continue to find a balance between green manufacturing and efficient production, providing a solid and flexible manufacturing foundation for the global packaging industry.