How does classic forging eliminate internal porosity and segregation in mold frames, improving overall material density and reliability?

Release Time : 2026-01-12

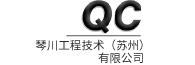

In high-end mold manufacturing, especially for precision injection molded mold frames used to produce automotive bumpers, dashboards, or large appliance housings, their performance depends not only on final geometric accuracy but also deeply on the intrinsic quality of the steel used. A seemingly uniform mold steel billet, if it contains defects such as microscopic porosity, compositional segregation, or coarse grains, even after precision cutting and polishing, is like a building on sand—easily deformed, cracked, or prematurely worn under high pressure, high temperature, and high frequency injection cycles. Classic forging is the key to solving this fundamental problem. It physically reshapes the "skeleton" of the metal, giving the mold frame material true density, uniformity, and long-term service reliability.

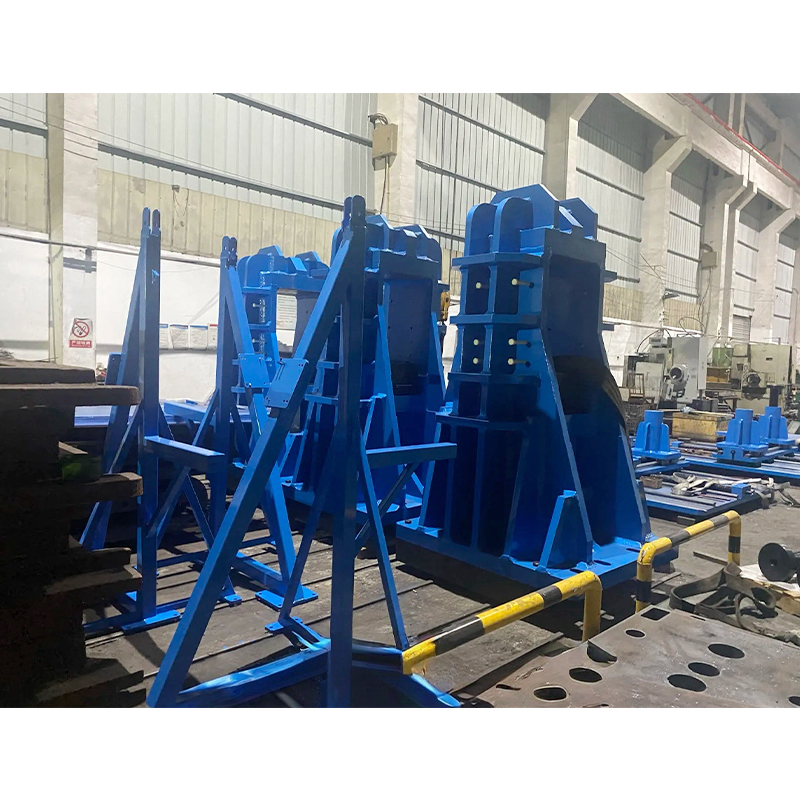

Forging is not simply hammering; it involves applying directional, controlled, and immense pressure to a steel ingot at high temperatures, causing it to undergo plastic flow and recrystallization. The core value of this process lies in breaking down the casting structure, welding internal voids, and homogenizing the chemical composition. During the solidification process, raw steel ingots inevitably form dendritic structures, leading to uneven distribution of alloying elements such as carbon, chromium, and nickel (i.e., "segregation"). Simultaneously, tiny pores or shrinkage porosity (i.e., "porosity") are generated in the cooling and contraction areas. These defects, though invisible to the naked eye, are breeding grounds for stress concentration and crack initiation. Classical forging, through multi-directional upsetting and repeated compaction, forces the metal flow lines to distribute rationally along the direction of force on the die, compressing and closing previously isolated pores, elongating and dispersing the segregated areas, ultimately forming a highly dense and uniform forged structure.

The benefits of this densification are comprehensive. First, mechanical properties are significantly improved. Dense materials have higher tensile strength, impact toughness, and fatigue life, capable of withstanding hundreds of tons of clamping force from an injection molding machine without deformation, and maintaining dimensional stability through millions of opening and closing cycles. Second, the heat treatment response is more consistent. Due to its uniform composition, the mold exhibits a smoother hardness distribution during subsequent tempering or surface hardening, avoiding localized soft spots or brittle areas and thus reducing the risk of abnormal wear or cracking during use. Furthermore, it offers superior machinability. The uniform and fine grain structure results in smoother cutting, reduced tool wear, and a smoother, mirror-like finish after polishing, which is particularly crucial for high-gloss components such as automotive headlight housings and panels.

Most importantly, forging optimizes the flow lines of the metal. In components like mold frames that bear complex loads, a well-distributed flow line can significantly improve fracture resistance. For example, if flow lines surround critical stress areas at the edges of the mold or around guide post holes, it acts like reinforcement in reinforced concrete, effectively preventing crack propagation. Cast or rolled materials often lack this directional strengthening ability.

Of course, to achieve these effects, forging itself must be "classic" and "controlled." This includes precise heating temperature control, reasonable deformation design, multiple heat treatments for uniform forging, and slow cooling or isothermal treatment after forging to prevent the generation of new internal stresses. Extensive forging not only fails to eliminate defects but may also introduce new problems such as folding and cracking. Therefore, the forging process itself for truly high-quality mold steel is a precise craft that integrates experience and science.

Ultimately, the value of classic forging is reflected throughout the entire lifecycle of the mold: from dimensional stability during the machining stage, to the first-time success rate during trial molding, and then to millions of trouble-free cycles in mass production—every step benefits from the unseen yet crucial dense internal structure.

In summary, classic forging is not only a traditional step in mold steel production but also a core engineering method for improving the inherent reliability of materials. It transforms mold frames from "usable" to "reliable," from "short-term service" to "long-term precision." In this era of pursuing zero-defect manufacturing, a meticulously forged mold steel is the most silent yet most solid foundation behind millions of perfect plastic products.

Forging is not simply hammering; it involves applying directional, controlled, and immense pressure to a steel ingot at high temperatures, causing it to undergo plastic flow and recrystallization. The core value of this process lies in breaking down the casting structure, welding internal voids, and homogenizing the chemical composition. During the solidification process, raw steel ingots inevitably form dendritic structures, leading to uneven distribution of alloying elements such as carbon, chromium, and nickel (i.e., "segregation"). Simultaneously, tiny pores or shrinkage porosity (i.e., "porosity") are generated in the cooling and contraction areas. These defects, though invisible to the naked eye, are breeding grounds for stress concentration and crack initiation. Classical forging, through multi-directional upsetting and repeated compaction, forces the metal flow lines to distribute rationally along the direction of force on the die, compressing and closing previously isolated pores, elongating and dispersing the segregated areas, ultimately forming a highly dense and uniform forged structure.

The benefits of this densification are comprehensive. First, mechanical properties are significantly improved. Dense materials have higher tensile strength, impact toughness, and fatigue life, capable of withstanding hundreds of tons of clamping force from an injection molding machine without deformation, and maintaining dimensional stability through millions of opening and closing cycles. Second, the heat treatment response is more consistent. Due to its uniform composition, the mold exhibits a smoother hardness distribution during subsequent tempering or surface hardening, avoiding localized soft spots or brittle areas and thus reducing the risk of abnormal wear or cracking during use. Furthermore, it offers superior machinability. The uniform and fine grain structure results in smoother cutting, reduced tool wear, and a smoother, mirror-like finish after polishing, which is particularly crucial for high-gloss components such as automotive headlight housings and panels.

Most importantly, forging optimizes the flow lines of the metal. In components like mold frames that bear complex loads, a well-distributed flow line can significantly improve fracture resistance. For example, if flow lines surround critical stress areas at the edges of the mold or around guide post holes, it acts like reinforcement in reinforced concrete, effectively preventing crack propagation. Cast or rolled materials often lack this directional strengthening ability.

Of course, to achieve these effects, forging itself must be "classic" and "controlled." This includes precise heating temperature control, reasonable deformation design, multiple heat treatments for uniform forging, and slow cooling or isothermal treatment after forging to prevent the generation of new internal stresses. Extensive forging not only fails to eliminate defects but may also introduce new problems such as folding and cracking. Therefore, the forging process itself for truly high-quality mold steel is a precise craft that integrates experience and science.

Ultimately, the value of classic forging is reflected throughout the entire lifecycle of the mold: from dimensional stability during the machining stage, to the first-time success rate during trial molding, and then to millions of trouble-free cycles in mass production—every step benefits from the unseen yet crucial dense internal structure.

In summary, classic forging is not only a traditional step in mold steel production but also a core engineering method for improving the inherent reliability of materials. It transforms mold frames from "usable" to "reliable," from "short-term service" to "long-term precision." In this era of pursuing zero-defect manufacturing, a meticulously forged mold steel is the most silent yet most solid foundation behind millions of perfect plastic products.