Can a crusher achieve efficient, stable, and durable ore processing under extreme conditions?

Release Time : 2026-01-26

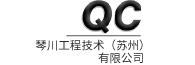

In the upstream processes of the metallurgical and mining industries, the crusher is a crucial link connecting raw ore mining with subsequent beneficiation and smelting. Day after day, it faces the fierce impact of hard rocks, high-silica ores, and even metal scrap, bearing the heavy responsibility of reducing large pieces of material to a processable particle size. This process not only tests the mechanical strength of the equipment but also places stringent requirements on its structural design, material toughness, and operational stability. A high-performance crusher equipment suite—comprising the main unit, transmission system, lubrication device, and intelligent monitoring module—is an industrial weapon designed to cope with extreme environments such as dust storms, heavy-duty impacts, and continuous operation.

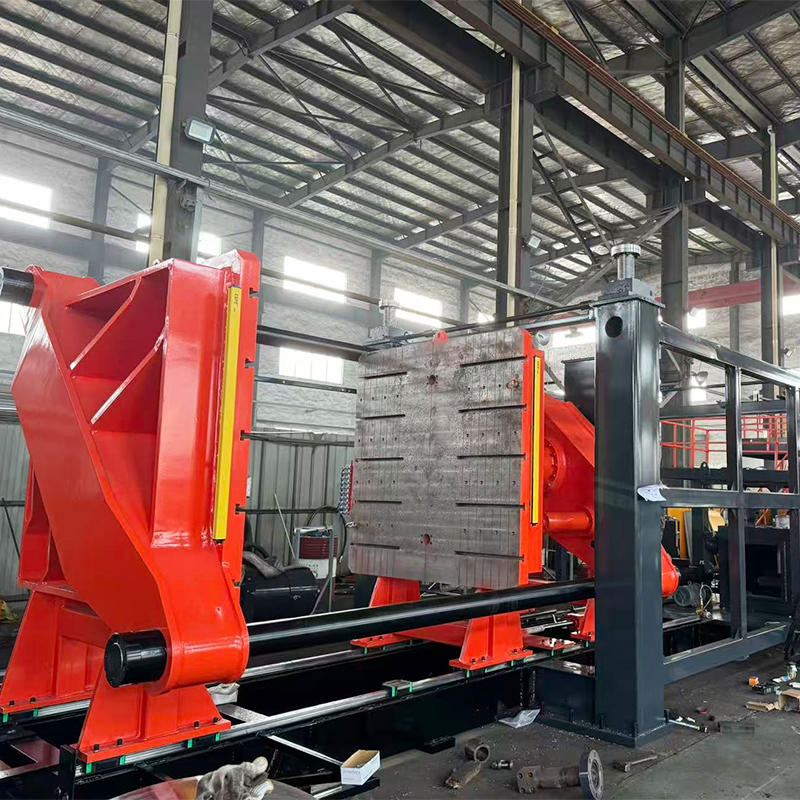

Its core capability is primarily reflected in its reliable crushing efficiency for high-strength materials. Whether it's a jaw crusher, cone crusher, or impact crusher, its core components are all cast or forged from special alloy steel. Key wear areas are hardened or inlaid with wear-resistant liners to ensure that geometric accuracy and structural integrity are maintained even after long-term friction and collision with high-hardness ores. Driven by powerful hydraulic or mechanical forces, moving components such as the moving jaw, grinding bowl, and crushing wall apply continuous pressure along precise trajectories, efficiently breaking down the ore through multiple actions of compression, splitting, and impact, preventing blockages or over-crushing.

In continuously operating mines, stability is far more valuable than peak performance. A high-quality crusher system integrates multiple protection mechanisms: an automatic lubrication system supplies oil to bearings and sliding surfaces at regular intervals to prevent temperature rise and wear caused by dry friction; a hydraulic clearing device quickly releases pressure when foreign objects enter, preventing damage to the spindle or frame; and an overload protection function monitors current and vibration in real time, triggering shutdown or adjustment upon abnormality to prevent cascading failures. These intelligent auxiliary systems significantly reduce the risk of unplanned downtime, ensuring efficient 24/7 operation of the production line.

A deeper value lies in its reliability and maintainability throughout its entire lifecycle. Modular design allows for quick and easy replacement of wear parts without disassembling the entire machine; critical components have sufficient safety margins to maintain fatigue life even with frequent start-stop cycles or load fluctuations; the sealed structure effectively prevents dust from entering the bearings and lubrication system, extending the service life of core components. Even in high-altitude, low-temperature, or humid environments, the equipment can maintain stable output through adaptive configuration.

Furthermore, modern crushers are gradually incorporating green and intelligent concepts. Optimized chamber design increases the crushing ratio and reduces energy consumption from repeated crushing; low-noise structures reduce the impact on the surrounding environment; some models are equipped with a remote monitoring platform, allowing real-time viewing of operating parameters and prediction of maintenance cycles, realizing a shift from "passive maintenance" to "proactive operation and maintenance." This technological evolution not only improves economic efficiency but also aligns with the development direction of sustainable mining.

Ultimately, the value of an excellent crusher lies not in its instantaneous crushing force, but in its continuous reliability over countless days and nights. Standing deep within the mine, it roars as it spews forth rocks, yet consistently delivers a stable particle size; it endures the harshest trials, yet its precise engineering logic safeguards the smooth operation of the entire process. As truckloads of raw ore are efficiently transformed into qualified raw materials, and as the feed to the smelting furnace flows continuously—behind this lies Crusher, with its steel frame and intelligent core, silently supporting the first line of defense in resource transformation. Because in the fundamental logic of heavy industry, true power lies not in destruction, but in controlled decomposition; true efficiency lies not in speed, but in continuity.

Its core capability is primarily reflected in its reliable crushing efficiency for high-strength materials. Whether it's a jaw crusher, cone crusher, or impact crusher, its core components are all cast or forged from special alloy steel. Key wear areas are hardened or inlaid with wear-resistant liners to ensure that geometric accuracy and structural integrity are maintained even after long-term friction and collision with high-hardness ores. Driven by powerful hydraulic or mechanical forces, moving components such as the moving jaw, grinding bowl, and crushing wall apply continuous pressure along precise trajectories, efficiently breaking down the ore through multiple actions of compression, splitting, and impact, preventing blockages or over-crushing.

In continuously operating mines, stability is far more valuable than peak performance. A high-quality crusher system integrates multiple protection mechanisms: an automatic lubrication system supplies oil to bearings and sliding surfaces at regular intervals to prevent temperature rise and wear caused by dry friction; a hydraulic clearing device quickly releases pressure when foreign objects enter, preventing damage to the spindle or frame; and an overload protection function monitors current and vibration in real time, triggering shutdown or adjustment upon abnormality to prevent cascading failures. These intelligent auxiliary systems significantly reduce the risk of unplanned downtime, ensuring efficient 24/7 operation of the production line.

A deeper value lies in its reliability and maintainability throughout its entire lifecycle. Modular design allows for quick and easy replacement of wear parts without disassembling the entire machine; critical components have sufficient safety margins to maintain fatigue life even with frequent start-stop cycles or load fluctuations; the sealed structure effectively prevents dust from entering the bearings and lubrication system, extending the service life of core components. Even in high-altitude, low-temperature, or humid environments, the equipment can maintain stable output through adaptive configuration.

Furthermore, modern crushers are gradually incorporating green and intelligent concepts. Optimized chamber design increases the crushing ratio and reduces energy consumption from repeated crushing; low-noise structures reduce the impact on the surrounding environment; some models are equipped with a remote monitoring platform, allowing real-time viewing of operating parameters and prediction of maintenance cycles, realizing a shift from "passive maintenance" to "proactive operation and maintenance." This technological evolution not only improves economic efficiency but also aligns with the development direction of sustainable mining.

Ultimately, the value of an excellent crusher lies not in its instantaneous crushing force, but in its continuous reliability over countless days and nights. Standing deep within the mine, it roars as it spews forth rocks, yet consistently delivers a stable particle size; it endures the harshest trials, yet its precise engineering logic safeguards the smooth operation of the entire process. As truckloads of raw ore are efficiently transformed into qualified raw materials, and as the feed to the smelting furnace flows continuously—behind this lies Crusher, with its steel frame and intelligent core, silently supporting the first line of defense in resource transformation. Because in the fundamental logic of heavy industry, true power lies not in destruction, but in controlled decomposition; true efficiency lies not in speed, but in continuity.